The touch screen by the touch detection means, and the touch screen controller; touch detecting member is mounted in front of the monitor screen, for detecting a user touch position, the accepted evacuation touch screen controller; the touch screen controller’s main role is to receive a touch from the touch point detecting means information, and convert it into contact coordinates, and then sent to the CPU, it is also capable of receiving commands issued by the CPU and to implement them.

A main types on a touch screen.

The touch screen works and information transmission medium, the touch screen is divided into four, namely resistive, capacitive sensors, infrared and surface acoustic wave. Each type of touch screen has its own advantages and disadvantages, to understand the kind of touch screen suitable for the kind of occasion, the key is to understand the working principle and characteristics of each type of touch screen technology . Following a brief description of the above-mentioned types of touch screen:

1. Resistive touch screen

This touch screen using the pressure sensors to control. A main part of the resistive touch screen is a display surface with the resistive films screen, which is a multilayer composite film, it is a layer of glass or hard plastic plate as a base, the surface coated with a layer of transparent metal (oxide transparent conductive resistance) conductive layer, above and then covered with a layer of outer surface hardening treatment, smooth plastic layer anti-rub, and its inner surface is also coated with a coating layer, and between them there are many of the small (less than 1/1000 inch) transparent separation point two conductive layers separated by insulation. When fingers touch the screen, the two conductive layers in the location of the touch point there the contact resistance changes, generating a signal in both X and Y directions, and then sent to the touch screen controller. The controller detects this contact, and calculate the position of the (X, Y), and then operates in accordance with the manner of the simulated mouse. This is the most basic principle of the resistive touch screen technology. Resistance class touch screen lies in materials science and technology, commonly used in transparent conductive coating material:

A, ITO, indium oxide, weakly conductive body characteristics are when the thickness is reduced to 1800 angstroms (Å = 10-10 m) or less, will suddenly become transparent, the light transmittance was 80%, and then thin down transmittance but decline, rising again to a thickness of 300 angstroms to 80 percent. ITO is all resistance technology touchscreen capacitive technology touch screen are the main material used in the face of resistance and capacitance touch screen technology is actually ITO coating.

Nickel gold coating, five-wire resistive touch screen of the outer conductive layer is good ductility nickel deposit coating materials, conductive outer layer due to the frequent touch, use a good ductility nickel deposit materials in order to extend the service life , but the technology costs more expensive. Nickel deposit conductive layer scalability, but only for a transparent conductor, is not suitable as the face of resistance touch screen, because it is high conductivity, and the metal is not easy to do very uniform thickness, suitable for voltage distribution layer, only as a probe layer.

1.1 Four-wire resistive touch screen

The two layers of the four-wire resistive analog technology transparent metal layer when each layer increase 5V constant voltage: a vertical direction, a horizontal direction. Need a total of four cables. Features: high-resolution, high-speed transfer reaction. Processing of surface hardness, reduce abrasion, scratching and anti-chemical treatment. With glossy and matte processing. Time correction, high stability, and never drift.

1.2 Five-wire resistive touch screen

The grassroots of the five-wire resistive touch screen panel technology to both directions of the voltage field through precision resistor networks are added to the conductive surface of the glass, we can easily understand the staggered working voltage field in both directions on the same work surface while the outer layer of nickel and gold conductive layer only just be used as a pure conductor, with a touch detecting a voltage value of the X-axis and Y-axis of the contact point of the inner ITO measured touch point position after timesharing.

The five-wire resistive touch screen inner ITO need four leads, the outer layer only for just a conductor, of the touch screen pinout total of five. Features: high-resolution, high-speed response. High surface hardness, reduce abrasion, scratch and anti-chemical treatment. The same point contact 30 million fair use. The conductive glass as the dielectric of the substrate. Time correction, high stability, and never drift. The five-wire resistive touch screen high-priced and high environmental requirements shortcomings

1.3 Resistive screen limitations

Whether it is a four-wire resistive touch screen or five-wire resistive touch screen, which is a kind of working environment completely isolated from the outside world, afraid of dust and water vapor, it can use any object to touch, can be used to draw and write, more suitable for the field of industrial control and limited office use. The resistive touch screen is a common drawback is the use of plastic material as the outer layer of the composite film, people do not know too hard may scratch the touch screen or use a sharp touch scrapped as a result. However, within limits, will only scratch injured outside the conductive layer and the outer conductive layer of scratch for five-wire resistive touch screen, four-wire resistive touch screen is fatal.

2. Capacitive touch screen

2.1 Capacitive touch screen technology

The current sense of the human body work. Capacitive touch screen is a four-story the composite glass screen, the inner surface of the glass screen and mezzanine each coated with a layer of ITO, the outermost protective layer of a thin layer of silica glass, laminated ITO coating as a face, the four corners leads to the four electrodes, the inner shield for the ITO in order to ensure a good working environment. When the finger touch on the metal layer, since the human field, the user, and the touch-screen surface is formed of a capacitive coupling, for a high-frequency current, the capacitor is the conductor directly, so fingers away from the contact point a small current. Current outflow from the electrodes on the four corners of the touch screen manufacturer, and current flows through four electrodes with fingers to proportional to the square of the distance, the controller through the accurate calculation of the four current ratio, come to the position of the touch point .

2.2 Capacitive touch screen defects

Transmittance and clarity of the capacitive touch screen is better than a four-wire resistive screen, of course, can not be compared and surface acoustic wave screen and five-wire resistive screen. Capacitive screen reflective serious, and a four-layer composite of the capacitive technology touch screen on the transmittance of light of each wavelength is uneven, there is the problem of color distortion, due to light reflection between the layers, also caused image characters blur. Capacitive screen in principle on the human body as an electrode using a capacitor element, when the conductor close to the coupling between the laminated ITO face sufficient amount of capacitance values, the current flow away enough to cause the capacitive screen malfunction . We know, although the capacitance value inversely with the inter-electrode distance, but it is proportional to the opposing area, and also related to the insulation coefficient of the medium. Therefore, when a larger area of the palm or handheld conductor was close to the capacitive screen rather than touch can cause a malfunction of the capacitive screen, in wet weather, this situation is particularly serious, hands held onto the monitor, the palm near the display 7 cm within or without the body near the display less than 15 cm can be caused by capacitive screen malfunction. Another disadvantage of the capacitive screen with a gloved hand or handheld no response when the touch of the non-conductive objects, this is because of the increased more insulating medium. The capacitive screen major drawback is the drift: When the ambient temperature, humidity changes, the environment field is changed, will cause the drift of the capacitive touch panel, resulting in inaccurate. For example: boot monitor temperature rise will cause drift: the user touches the screen while the other hand, or on one side of the body near the display will drift; drift back large objects moving near the capacitive touch screen when you touch someone come around to watch also congenital deficiency will cause drift; capacitive screen drift reasons are technical, environmental potential surface (including the user’s body) with capacitive touch screen from distant than finger multi area, they have a direct impact on the touch location determination . In addition, in theory, many should be a linear relationship between the actually is nonlinear, such as: the total amount of current body weight, or a different degree of wet fingers sucked is different, and the total amount of current change and the four stars current amount changes in the non-linear relationship, the capacitive touch screen with this custom of the four corners of the polar coordinate system is not yet on the origin of the coordinate, the controller can not detect drift and recovery and the completion of the four A / D, the value of the four sub-flows to the touch point on a Cartesian coordinate system X, Y-coordinate value of the calculation process is complex.

The absence of the origin, the drift of the capacitive screen is cumulative, at the job site often need calibration. The capacitive touchscreen outermost protection of silica glass scratch resistant good, but afraid of nails or hard objects knocking, knocked a hole in it will hurt the mezzanine of ITO, whether it is hurt laminated ITO hurt during transport or install the inner surface of the ITO layer capacitance screen can not work properly.

3. Infrared touch screen

Infrared touch screen is the use of the X, Y direction clouds infrared matrix to detect and locate a user’s touch. A circuit board frame infrared touch screen installed in the front of the display board in the screen edges arrangement of infrared emission tube and infrared receiver tube, one-to-one correspondence to the formation of the horizontal and vertical cross the infrared matrix. User when the touch screen, the fingers will be blocked if they had been the location of two infrared, which can determine the position of the touch points on the screen. Any touch object can change the contact infrared touch screen operation. The earlier conceptual, infrared touch screen is low-resolution, touch restricted and vulnerable to environmental interference and malfunction of technical limitations, thus once fade out over the market. After second-generation infrared screen a partial solution to the problem of resistance to light interference, and the third and fourth generation also improved to enhance the resolution and stable performance on key indicators or performance, but did not have a qualitative leap. However, people know about touch screen technology, infrared touch screen is not current, voltage and electrostatic interference, suitable for harsh environmental conditions, infrared technology is the ultimate touch screen products trends. Acoustics and materials science technology touch screen has its insurmountable barrier, such as a single sensor is damaged, aging, touch interface afraid contaminated destructive use, maintenance of complicated problems. Infrared touch screen as long as real to achieve high stability and high resolution, and will replace other technology products into the mainstream of the touch-screen market. The past infrared touch screen resolution is determined by the infrared on the number of tubes in the framework, so the lower resolution, the major domestic products on the market for 32×32, 40X32, in addition to the infrared screen is more sensitive to light environmental factors, illumination changes. large misjudgment or even crash. The weaknesses of the domestic dealer sales promotion of these is the foreign non infrared touch screen Infrared screen. The latest technologies of the fifth generation of infrared screen resolution depends on the infrared tube on the number of scan frequency, and the difference algorithm, a resolution has been reached 1000X720, As the instability of the infrared screen light conditions, from the second-generation infrared touch screen had better overcome resistance to light interference this vulnerability. Fifth-generation infrared touch screen is a whole new generation of smart technology products, it is 1000 * 720 high resolution, multi-level self-regulation and self-recovery hardware adaptability and highly intelligent discriminant recognition, can be a long time in a variety of harsh environments under the arbitrary use. Extensions and can be customized for the user, such as network control, acoustic sensing, human proximity sensing, user software encryption protection, infrared data transmission. Original media campaign infrared touch screen another main drawback uprising sexual difference, In fact, the infrared screen can choice any customer that satisfied riot glass and will not increase too much cost and impact of using performance, other touch screen that can not follow the example of the.

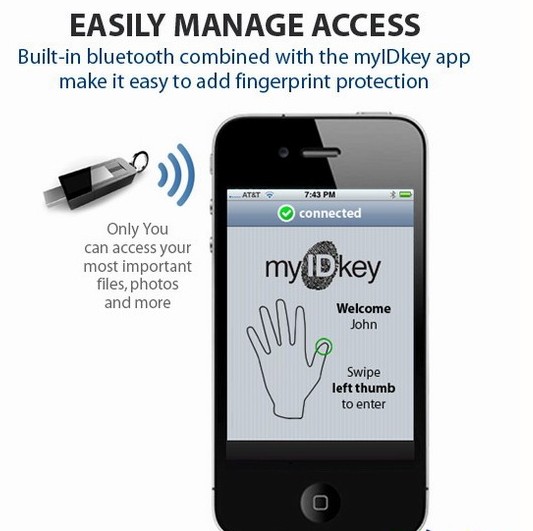

ing, when scanned your thumb, also the need for self-setting gesture unlock.

ing, when scanned your thumb, also the need for self-setting gesture unlock.